How to check the quality of mineral fiber ceiling tile?

Because mineral fiber ceilings have the advantages of good sound absorption, fire prevention, moisture resistance, and environmental protection, they are widely used in the indoor ceiling environment of various buildings. Compared with many gypsum boards, aluminum gusset boards, and calcium-silicon boards, mineral fiber ceilings have irreplaceable advantages in terms of indoor acoustic environment control, product modeling, and comprehensive cost-effective indicators, especially in the processing of building ceilings.

The sound-absorbing panels and ceilings commonly used in the market refer to mineral fiber ceilings, because among all ceilings, only mineral fiber ceilings have sound-absorbing properties. The mineral fiber ceiling is made of mineral particle fiber cotton as the main raw material, adding other raw materials, stirring and shaping, drying and cutting, embossing and spraying. The main material of the mineral fiber ceiling is slag, which is a non-combustible material. Therefore, the mineral fiber ceiling has good fire and heat insulation performance after being formed. There are different brands of mineral fiber ceilings on the market, and the production methods of each manufacturer are also different. So, how to distinguish the quality of mineral fiber ceiling?As a supplier of mineral fiber ceiling tiles will tell you.

First, look at the mineral fiber ceiling material

The production of mineral fiber ceilings must be controlled from the raw materials. A good mineral fiber ceiling must also use high-quality mineral fiber cotton; and the slag used by some small manufacturers in the market to produce mineral fiber ceilings is natural slag, which is easy to find. The resulting mineral fiber ceiling contains impurities, has uneven weight, and is easily deformed. When identifying the mineral fiber ceiling, we carefully observe the quality of the mineral wool from the exposed side of the mineral fiber ceiling, whether it is uniform, and whether the color difference of the mineral wool is consistent. This is the basic method to distinguish the quality of mineral fiber ceiling.

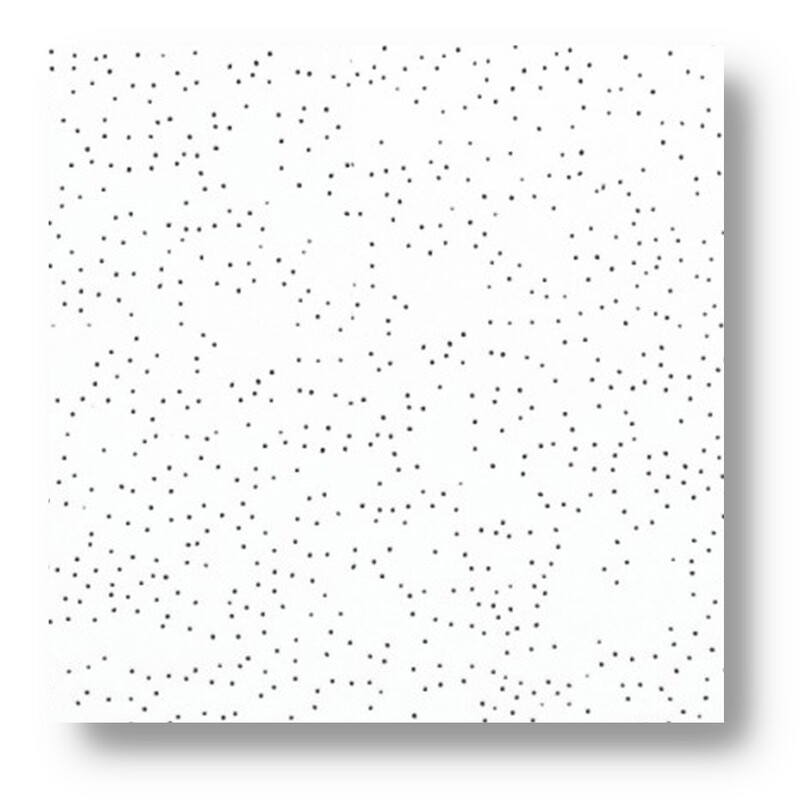

Secondly, look at the surface of the mineral fiber ceiling

Mineral fiber ceilings will be surface treated during production. Regular manufacturers will polish and paint the surface of the mineral fiber ceiling. This is where mineral fiber ceilings show their quality value. Therefore, another criterion for judging the quality of mineral fiber ceilings is to check whether the color difference of the surface spraying treatment is consistent, whether the back coating is up to the standard, whether there is sticking mineral wool, and whether there are protrusions on the surface.

Third, look at the shape of the mineral fiber ceiling

Our common mineral fiber suspended ceiling is 600*600 white. The ceiling shapes that can be used are relatively simple, and high-quality mineral fiber ceilings can also use a variety of shapes. The surface of the mineral fiber ceiling can be processed in a variety of colors and shapes, such as black mineral fiber ceiling, corrugated mineral fiber ceiling and so on. High-quality mineral fiber ceilings can be made in layers, giving customers more choices. However, small mineral fiber ceiling manufacturers do not have the production and design capabilities of this mineral fiber ceiling.

Fourth, look at the performance of the mineral fiber ceiling

The performance of the mineral fiber ceiling is a standard that simply reflects the quality of the mineral fiber ceiling. On the sample label of the mineral fiber ceiling, the general manufacturer will attach the corresponding information of the mineral fiber ceiling, including the sound absorption performance index, fire performance index, and sound insulation performance index of the mineral fiber ceiling. , Moisture-proof performance indicators, etc. Generally, in engineering ceilings, mineral fiber ceiling manufacturers are required to issue mineral fiber ceiling performance test reports of corresponding quality products to determine whether the mineral fiber ceiling can meet the required use standards

When choosing a mineral fiber ceiling, you should not only look at the price, but also the quality of the mineral fiber ceiling product. Only good mineral fiber ceilings are better for us. Among the qualified mineral fiber ceilings, it is best to choose the one with higher cost performance.