3 Essential Steps in the Mineral Fiber Ceiling Tile Manufacturing Process

3 Essential Steps in the Mineral Fiber Ceiling Tile Manufacturing Process

SLD is a leading manufacturer of Mineral Fiber Ceiling Tiles, delivering top-quality ceiling solutions for both commercial and residential buildings. Our tiles are widely recognized for their acoustic performance, fire resistance, moisture resistance, and aesthetic appeal. But have you ever wondered how these ceiling tiles are made? In this article, we will walk you through the three main steps in the Mineral Fiber Ceiling Tile manufacturing process that ensure high-quality, durable, and functional products.

Step 1: Raw Material Preparation and Blending

The first and most critical stage in manufacturing Mineral Fiber Ceiling Tiles is the preparation and blending of raw materials. At SLD, we use a proprietary mix of mineral wool fibers, recycled newspaper, perlite, clay, and binders. These components are selected for their ability to enhance fire resistance, thermal insulation, and acoustic control.

During this step, the mineral wool fibers are first loosened and uniformly dispersed. Recycled paper is pulped and added to the mixture to improve texture and reduce environmental impact. Perlite, a natural volcanic glass, is incorporated to enhance lightweight and insulating properties. Clay improves rigidity, while binders ensure the integrity of the final product.

This carefully engineered blend is processed in a slurry tank where the consistency and chemical composition are closely monitored by our engineers. Achieving the right fiber length, density, and composition is essential to ensure the performance of the final Mineral Fiber Ceiling Tiles.

Step 2: Sheet Forming and Dehydration

Once the raw materials are blended into a slurry, they are fed into a continuous sheet-forming machine. This step is often referred to as the wet forming process. The slurry is spread across a moving screen that allows water to drain through, leaving behind a wet fiber mat that takes the form of a tile.

At SLD, we employ advanced vacuum dehydration systems that speed up water removal, enabling efficient processing without compromising tile strength. The semi-solid fiber mats are then cut into desired tile sizes and transported into a multi-stage dryer. During this drying phase, all remaining moisture is eliminated, and the tile gains the necessary rigidity and shape stability.

This critical step defines the dimensional accuracy and physical performance of Mineral Fiber Ceiling Tiles. Improper drying can lead to warping, cracking, or inconsistent density, so SLD applies rigorous quality control throughout this phase.

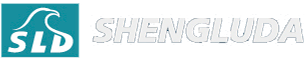

Step 3: Surface Finishing and Coating

The final stage in the manufacturing process involves finishing the surface of the dried tiles. SLD applies a specially formulated coating that provides an attractive, durable, and paintable surface. This coating also enhances the tiles’ resistance to humidity and microbial growth, making them ideal for use in high-moisture environments like bathrooms, kitchens, and basements.

Our finishing process includes surface embossing, edge cutting, and painting. Embossing allows us to create various textures and patterns that match diverse interior designs. We also offer both square and tegular edge profiles to suit different ceiling grid systems.

Once the Mineral Fiber Ceiling Tiles are finished, each batch undergoes strict quality testing for dimensions, sound absorption (NRC), fire resistance (ASTM E84), and humidity tolerance (RH rating). Only tiles that meet all our stringent quality standards are packed and shipped to customers worldwide.

Why Choose SLD Mineral Fiber Ceiling Tiles?

SLD has built a solid reputation as a trusted supplier of high-performance Mineral Fiber Ceiling Tiles. Our production lines are equipped with automated machinery and real-time quality monitoring systems to ensure consistent product excellence. We also prioritize environmental responsibility by incorporating high levels of recycled content in every tile we produce.

Our Mineral Fiber Ceiling Tiles are widely used in schools, offices, hospitals, shopping centers, and public infrastructure projects due to their durability, cost-effectiveness, and design versatility.

Conclusion

The manufacturing of Mineral Fiber Ceiling Tiles is a highly controlled and precision-driven process involving raw material blending, wet forming, and advanced finishing. At SLD, every step is optimized to ensure the highest quality standards and to deliver superior acoustic and aesthetic performance.

If you’re looking for reliable, eco-friendly, and cost-effective ceiling solutions, SLD Mineral Fiber Ceiling Tiles are the ideal choice. Contact our team today to learn more about our product range and customization options.